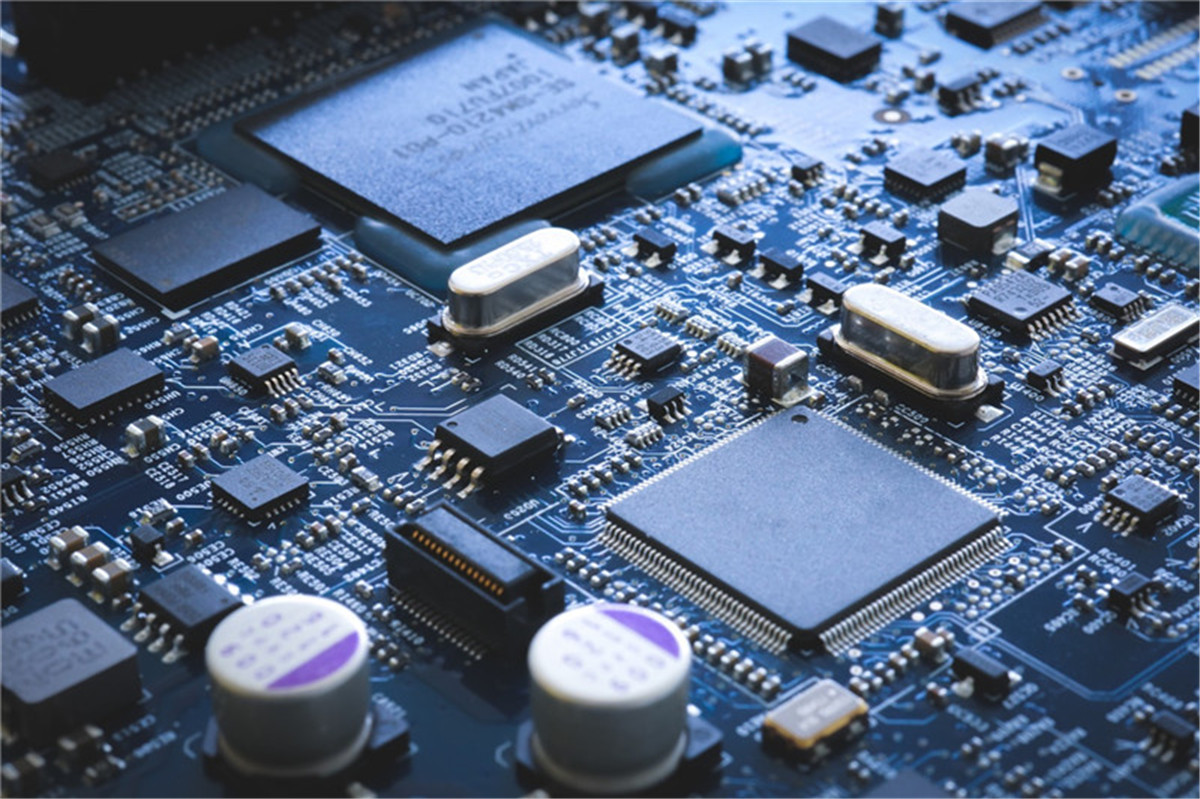

PCB Assembly for Prototyping: Speed vs. Cost

As a content writer in the PCB (Printed Circuit Board) assembly industry, I understand that for many businesses, time-to-market and cost-effectiveness are crucial factors when choosing a prototyping service. When deciding between speed and cost in PCB assembly, it's essential to strike a balance that meets your project's specific needs. In this article, we'll explore the trade-offs between rapid prototyping and affordable pricing, helping you make an informed decision.

1. Understanding the Process

- Rapid prototyping allows you to get a functional prototype quickly, often within days or weeks, thanks to advanced technologies like automated pick-and-place machines and 24/7 manufacturing facilities.

- Traditional prototyping, on the other hand, may take longer, sometimes months, but it can offer more customization options and better control over the design process.

1. Cost Breakdown

- Faster prototyping usually comes with a premium due to the high demand for short lead times and specialized equipment. Rush fees and priority handling can increase costs significantly.

- On web link , slower prototyping processes might offer more competitive pricing since they don't require the same level of resources or urgency.

1. Quality vs. Speed

- While speed can be impressive, it doesn't always guarantee perfect quality. Lower turnaround times may mean less stringent quality checks, so be sure to discuss your quality expectations with your assembly partner.

- Conversely, slower prototyping services often adhere to higher quality standards, ensuring a more reliable product from the start.

1. Iteration and Learning Cycles

- For projects with multiple design iterations, rapid prototyping can save time as you can iterate quickly and learn from each version. This speed-to-market advantage can be invaluable.

- However, if your project requires extensive revisions, the cost of multiple prototypes may offset the time saved.

1. Flexibility and Customization

- Traditional prototyping allows for more customization and fine-tuning of your design, which can be crucial for niche applications or unique requirements.

- Rapid prototyping, while less flexible, may still offer some customization options, but it's essential to communicate your exact specifications upfront to minimize surprises.

1. Risk Management

- With a slower prototyping process, you have more time to identify and address potential issues before moving to mass production. This can reduce risks and minimize potential production delays.

- If you're working on a tight deadline or need a proof-of-concept quickly, rapid prototyping can help mitigate risk by getting your product to market faster.

1. Choosing the Right Balance

- Assess your project's urgency, budget, and design complexity to determine the best approach. Consider discussing your needs with experienced assembly partners who can offer tailored solutions.

- Remember, compromising on one factor doesn't necessarily mean sacrificing the other. It's about finding the right balance that aligns with your business objectives.

In conclusion, when deciding between speed and cost in PCB assembly for prototyping, weigh the advantages and disadvantages based on your project's unique requirements. A well-informed choice will help you achieve your goals without breaking the bank or delaying your product's launch. By understanding the trade-offs and consulting with industry experts, you can find the perfect prototyping solution for your next project.